Phone Number

+91-22-66287900

When selecting the correct type of pipe for your project needs, it’s essential to consider

various factors like pipe size, wall thickness, material, and manufacturing process. Two popular

types of welded pipes are Electric Resistance Welded (ERW) and Electric Fusion Welded (EFW).

Although both share many similarities, they differ in manufacturing processes, welding

technology, and practical uses. In this blog post, we will discuss various aspects of ERW Pipe

vs EFW Pipe to help you make an informed decision.

ERW pipe is made from a strip of steel that is rolled and welded to create a line. The welding

process used for ERW pipe creates a robust and reliable seam resistant to leaks and corrosion.

This type of pipe is most commonly used for low-pressure applications, such as carrying water or

natural gas.

EFW pipe is made from a strip of steel that is rolled and welded to create a line. The welding

process used for EFW pipe creates a robust and reliable seam resistant to leaks and corrosion.

This type of pipe is most commonly used for high-pressure applications, such as carrying oil or

steam.

The main difference between ERW and EFW pipe is the welding process used. ERW pipe is made with

a resistance welding process that creates a robust and reliable seam. EFW pipe is made with an

electrode fusion welding process that creates an even stronger seam. Both types of pipe are

resistant to leaks and corrosion, but EFW pipe can handle higher pressures.

Types of EFW Pipe

Two primary types of EFW pipes are longitudinal Welding and spiral welding. Longitudinal Welding, also known as straight seam welding, involves welding two edges of a steel plate or coil together to create a long and straight pipe. On the other hand, Spiral Welding involves rolling a steel plate or coil into a pipe shape and welding the seams together along a spiral path.

Longitudinal Welding

Longitudinal Welding is a type of Welding that involves joining two materials along their length. It is used in many applications, such as pipe fabrication, shipbuilding and automotive engineering. The most popular longitudinal welding techniques are submerged arc welding (SAW) and gas metal arc welding (GMAW). SAW requires electrodes to be melted in a shielded environment by supplying additional current through an electrode wire. At the same time, GMAW uses heat generated from an electric arc between the base material and a consumable wire to join them together. Longitudinal Welding is advantageous for its accuracy in controlling the weld’s parameters such as speed, width, overlap etc., relative ease of operation compared to other types of Welding, improved stability thanks to the presence of specific tools for it, and less chance of distortion during cooling down due to its uniform heating over extended lengths. Additionally, it offers high productivity with fewer defects using automated processes like robot/machine-guided methods or mechanized track-based technologies, which ultimately result in better-quality welded joints.

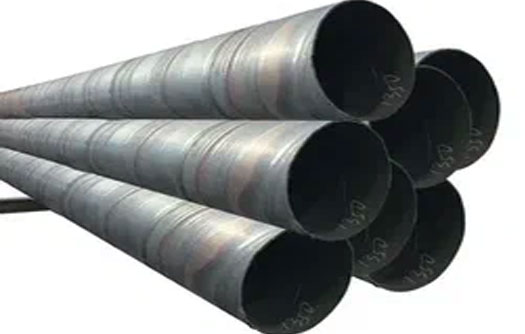

Spiral Welding

Spiral welding is a common welding technique used in many industries. This method is advantageous due to its structural strength and cost efficiency compared to other welding methods. In this process, the two ends of the workpiece (pipe or tube) are first prepared by forming a V-shaped groove at their respective edges, followed by adding filler material between them, which bridges the gap. Then, an electric arc is applied along with heat from turning rollers, which starts to melt the filler material, creating a spiral weld pattern as it moves along the length of both pieces simultaneously. The result is a strong and reliable joint with high resistance to fatigue and corrosion for applications requiring higher-grade materials and protection against various chemical agents. It is suitable for numerous engineering situations in sectors such as oil & gas, automotive, aerospace, etc

Advantages of ERW Pipe

ERW pipe has several advantages over other types of pipes, including:

Manufacturing Process

ERW Pipes are made by generating high-frequency electrical resistance to the edges of the metal strips, resulting in fusion by heating the contacted surface to the melting point. On the other hand, EFW Pipes are made by heating a flat metal piece and forming it into a cylindrical shape by melting the edges together. Both processes produce high-quality steel pipes, but ERW Pipes are considered more efficient in time and energy consumption.

Applicable Uses

ERW Pipes and EFW Pipes have various use cases, and the choice depends on the specific needs of your project. ERW Pipes are commonly used in industries such as oil and gas, construction, agriculture, automotive, etc. Due to their cost-effectiveness and durability, they are ideal for applications that involve transporting gas, water, or other liquids and structural applications. EFW Pipes, on the other hand, are used in high-performance applications that require tight tolerances, such as nuclear reactors, thermoelectric power plants, and heat exchangers